DESIGNING

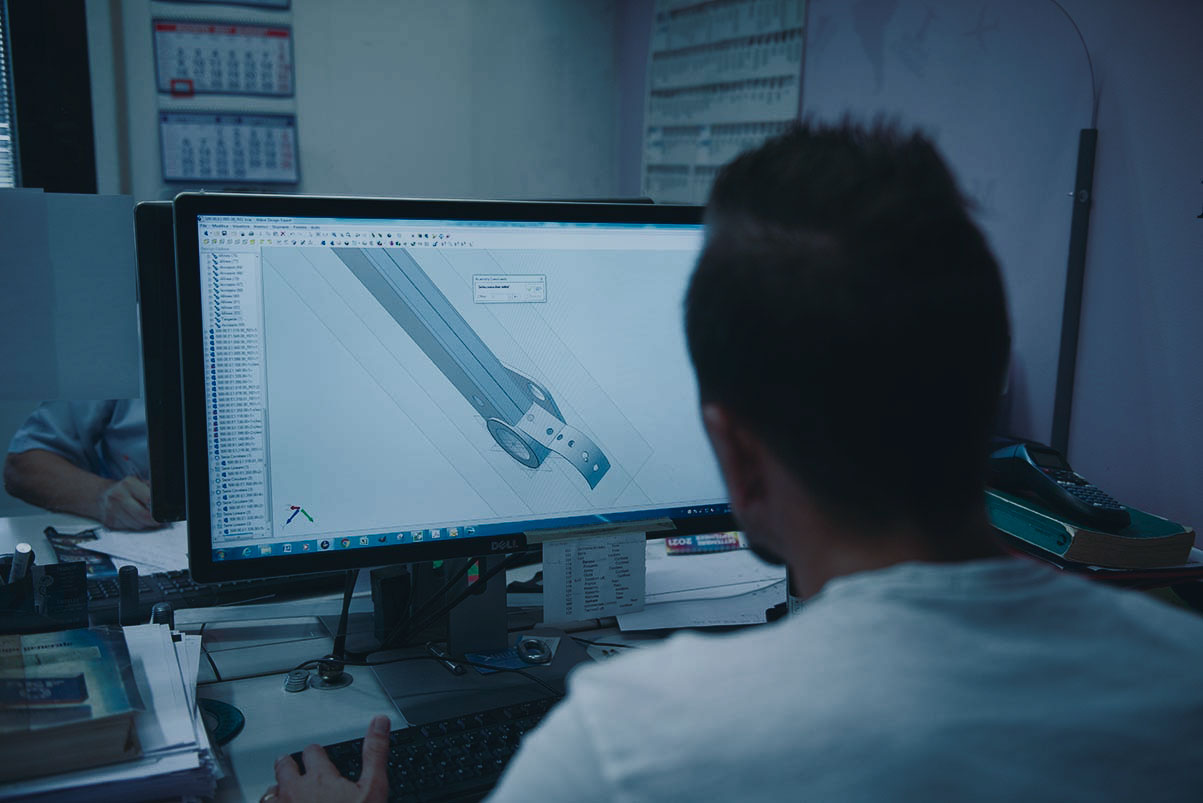

From the flat CAD projects, to their development in 3D, thanks to always up-to-date technologies our design projects really show the state-of-the-art, and are the basis for manufacturing high quality attractions.

THEMING

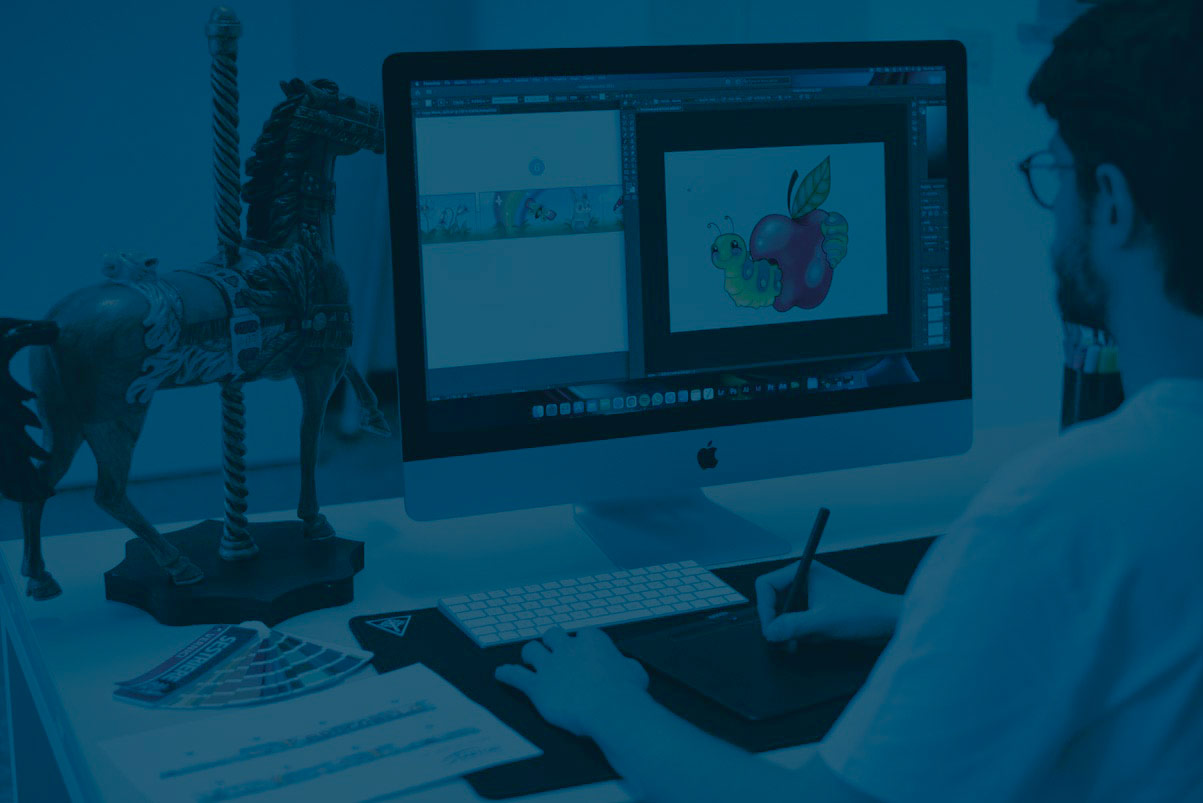

Theming, colors, led lights. Our creative decorators suggest high-fidelity drafts so that you can really have a glimpse of the finished product before the actual painting starts.

PRODUCING

FIBERGLASS: All the vehicles at Sartori Rides are made inside our fiberglass department where our personnel give shape meticulously to cups, planes, cars, and every kind of seat.

PAINTING: In collaboration with the customization department, our decorators breathe life into the draft by painting the fiberglass vehicles with eye-catching colors and shadings.

ASSEMBLING

Once every component is finished, our staff starts the mechanical assembly.

LEDs are implemented by our electricians, who are also the minds behind the most spectacular light tricks and motions of the attraction.

Now, onto delivery.

TESTING

Depending on the requirements, a team of supervisors checks and tests the ride, in order to deliver ready-to-operate attractions to our clients.

All attractions are fully approved before leaving the factory.

SUPPORTING

The relationship between Sartori and the clients doesn’t end with the delivery: our personnel is always available for after-sales assistance, also with a spare parts supply service.

![]() DESIGNING

DESIGNING

![]() THEMING

THEMING

![]() PRODUCING

PRODUCING

ASSEMBLING

ASSEMBLING

![]() TESTING

TESTING

![]() SUPPORTING

SUPPORTING

![]() DESIGNING

DESIGNING

Our amusement rides are designed by a highly skilled technical team of engineers and technicians.

From the flat CAD projects, to their development in 3D, thanks to always up-to-date technologies our design projects really show the state-of-the-art, and are the basis for manufacturing high quality attractions.

![]() THEMING

THEMING

Each and every Sartori attraction is made following the clients’ aesthetical requests, preferences and needs.

Theming, colors, led lights.

Our creative decorators suggest high-fidelity drafts so that you can really have a glimpse of the finished product before the actual painting starts.

![]() PRODUCING

PRODUCING

CARPENTRY: Our team of specialized workers follow the most delicate processes of the construction: welders, carpenters and metal workers forge the “bone structure” of each attraction.

FIBERGLASS: All the vehicles at Sartori Rides are made inside our fiberglass department where our personnel give shape meticulously to cups, planes, cars, and every kind of seat.

PAINTING: In collaboration with the customization department, our decorators breathe life into the draft by painting the fiberglass vehicles with eye-catching colors and shadings.

ASSEMBLING

ASSEMBLING

Once every component is finished, our staff starts the mechanical assembly.

LEDs are implemented by our electricians, who are also the minds behind the most spectacular light tricks and motions of the attraction.

Now, onto delivery.

![]() TESTING

TESTING

Depending on the requirements, a team of supervisors checks and tests the ride, in order to deliver ready-to-operate attractions to our clients.

All attractions are fully approved before leaving the factory.

![]() SUPPORTING

SUPPORTING

The relationship between Sartori and the clients doesn’t end with the delivery: our personnel is always available for after-sales assistance, also with a spare parts supply service.